Versatile Spill Safety Solutions for Janitorial and Sanitary Applications

Janitorial Sanitary

FyterTech offers professional-grade spill absorbents perfectly suited for janitorial and sanitary applications. Our maintenance absorbents recover both oil- and water-based spills at the same time, providing versatile solutions that keep facilities clean, safe, and operationally efficient.

Liquid Safety Solutions for Janitorial and Sanitary use

This is just a selection of spill products from our wider product range that are particularly suited to Janitorial and Sanitary applications.

Which type of spill absorbent should I choose?

For most, if not all janitorial and sanitary applications, a Maintenance absorbent will be best suited. Maintenance absorbents recover both oil- and water-based spills or leaks at the same time.

Maintenance absorbents (sometimes referred to as universal) are grey and/or black and will absorb both oil-based and water-based fluids at the same time. These can be used indoors or outdoors but will take up a lot of water-based fluids at the same time as oil-based fluids.

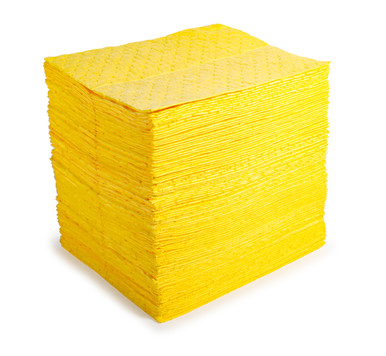

Chemical absorbents are yellow. This is to signify to emergency services personnel that unknown or hazardous pollutants may be present, and that extreme caution should be shown when recovering and disposing of these contaminated sorbents.

Liquid spill solutions for cleaning and maintenance tasks

To manage fluids that that are regularly come into contact with, or are used on hard surfaces there are a range of absorbent products available.

Spill Absorbent Pads are ideal for wiping surfaces, machinery or equipment. Laminated pads are the strongest, bonded pads feature sonic bond points which offer some additional strength over unbonded products. Both laminated and bonded pads feature perforations, allowing just the right amount of absorbent to be selected resulting in better cost effectiveness.

Spill Absorbent Rolls of absorbent with a laminated layer can be placed alongside machinery and will accept foot traffic and in some cases wheeled traffic. They prevent slips and trips by drawing up fluids from hard surfaces. These products also feature perforations so that the correct amount can easily be torn-off.

Spill Depot absorbent dispensers keep absorbents stored and ready for use. These can be regularly replenished to ensure absorbents are always at hand. Available in a range of sizes and either wall-mounted or free-standing formats ensures there will be a configuration suitable for any business’s requirements.

Spill Recovery Secondary Containment storage and handling equipment for storing fluids ready for use in planned maintenance ensures fluids are handled safely. They also ensure any spills or leaks are prevented from escaping into the drains by the self-contained sump capacity.

Recovering unplanned spills or leaks

For unexpected spills and leaks it is essential to have the correct liquid safety solutions in place to be able to respond accordingly. In most cases a spill kit or range of strategically located and readily available spill kits will provide all the absorbents and a container needed to recover the spill.

Portable spill kits allow a quantity of absorbents to be taken to the site of a spill or leak quickly. Available in 10-50L clip top bags with 50L vinyl satchel options are available.

Static spill kits are best located where there is a chance of a spill occurring and providing mitigation against the risk. Available in an 80L round bin.

Wheeled bin spill kits range from 120-1000L. These highly manoeuvrable spill kits are an essential choice for dealing with unplanned spill types. To protect the initial investment, we provide spill kit refills to ensure the spill kits are always ready and on stand-by.

Granules in our opinion will always provide a better spill recovery option when all aspects of safety, cost and disposal are taken into consideration. However we do provide a range of granular absorbent for those who prefer it.

The cost of slips and trips

31% of workplace accidents involve slips, trips or falls. This comes at a cost of around £512m a year to UK industry and businesses. These devastating costs to both individuals and to businesses is the reason why having a liquid safety solution is so important. Contact us today for more information.

The law from the HSE

The Health and Safety at Work etc Act 1974 (HSWA)

The Health and Safety at Work Act 1974 requires employers to ensure the health and safety of all employees and anyone affected by their work, so far as is reasonably practicable, which means balancing the level of risk against the measures needed to control the risk in terms of money, time or trouble. This includes taking steps to control slip and trip risks.

Employees have a duty to take care of their own health and safety and that of others and must use any safety equipment provided.

Health and Safety at Work etc Act 1974

The Management of Health and Safety at Work Regulations 1999 (Regulation 3)

Build on the HSWA and include duties on employers to assess risks (including slip and trip risks) and take action where necessary.

Management of health and safety at work

The Workplace (Health, Safety and Welfare) Regulations 1992 (Regulation 12)

Require floors to be suitable, in good condition and free from obstructions. People should be able to move around safely.

The Workplace (Health, Safety and Welfare) Regulations 1992

Site Surveys and Spill Recovery training

To help you identify spill and leak risks we can provide a site survey. An experienced and highly knowledgeable member of our team will attend your premises and provide a written report identifying the risks. Along with the risk identification, a suggestions of liquid safety solutions will be suggested.

To allow a business’s employees to better respond to a spill we provide spill training to ensure that in the event of a spill everybody knows how to safely respond and follow a set procedure.