GB

Explaining Spill Absorbents | Expert Advice From a Spill Manufacturer

Absorbent Pads and Rolls for Fluid Spill Recovery

Selecting the right absorbent is crucial for effective fluid spill management.

FyterTech Nonwovens manufactures meltblown absorbent pads and rolls in various constructions, weights, sizes, and formats, designed to absorb different fluid types. Discover the various absorbent options, their applications, and how to select the right product for effective spill recovery.

How to Choose the Right Absorbent for Oil, Water, and Chemical Spills

To simplify the process, the industry uses three globally recognised colours to identify absorbent types:

- White – Oil Only: Best for absorbing oil-based fluids.

- Grey – Maintenance: Absorbs both water- and oil-based fluids.

- Yellow – Chemical: Designed for hazardous or corrosive chemical spills.

Types of Spill Absorbents

Maintenance Absorbents

Typically grey or black, maintenance absorbents are designed to absorb both oil- and water-based fluids. These versatile absorbents are ideal for managing indoor spills and general fluid recovery tasks.

Oil-Only Absorbents

Oil-only absorbents are white in colour and specifically designed for absorbing oil-based fluids. These hydrophobic pads are ideal for outdoor use, as they only absorb oil and repel water, making them perfect for managing oil spills on bodies of water or other outdoor environments.

Chemical Absorbents

Yellow absorbents are specially formulated to handle chemical spills, including aggressive, corrosive, or unknown substances. These can be used in both indoor and outdoor environments, making them suitable for various industrial applications.

Exploring Absorbent Constructions: Bonded, Unbonded, and Laminated Options

Our absorbent pads and rolls are available in a range of construction types and weights. The construction influences the absorbent's durability, wicking performance, and slip resistance, which is important when used as floor coverings.

Bonded Absorbents

Bonded absorbents are created by passing unbonded meltblown mats through sonic heads that fuse the fibres at specific points. This process improves strength and reduces linting. However, due to the small bond points (covering about 5% of the pad), these products may not be as durable as laminated versions, making them a more economical option.

Unbonded Absorbents

Unbonded meltblown absorbents are made by melting polypropylene resin and blowing fine fibres to create a continuous mat. These absorbents offer fast absorption but have limited durability. Unbonded absorbents are typically available only in Oil-Only format, which makes them suitable for recovering oil-based spills.

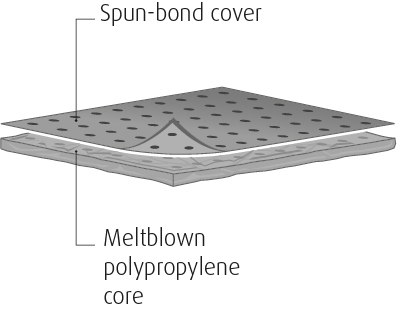

Single Laminated Absorbents

Single laminated absorbents are our top recommendation for most applications. A thin layer of no-lint spun-bond material is sonically attached to the meltblown core, which greatly reduces linting and increases strength. Additionally, these absorbents are less slippery when used as floor coverings, making them ideal for high-traffic areas.

Why Choose UK-Made Meltblown Absorbents for Spill Management?

Our meltblown polypropylene non-woven absorbents, made in the UK, are produced using 100% polypropylene material. The fibres are melted and "blown" under high pressure, resulting in a high-loft structure that enhances absorbency and durability.

- Strength and Durability: These absorbents offer excellent strength, heat resistance, and long-lasting performance.

- Absorbency: The high-loft design provides superior absorbency, allowing for quick and efficient spill recovery.

- Oil-Only: Ideal for oil-based spills, particularly on water, thanks to their hydrophobic properties.

- Hydrophobic and Hydrophilic Properties: Oil-Only absorbents repel water and attract oil-based fluids, while Maintenance absorbents are hydrophilic, absorbing both oil- and water-based fluids.

- Chemical Absorbents: These absorbents feature a yellow pigment to indicate that they are suitable for hazardous chemical spills, ensuring that users can quickly identify the correct product.

Common Applications for Absorbent Products

- Oil Spill Recovery: Use Oil-Only absorbents for effective recovery of oil spills in outdoor and aquatic environments.

- General Maintenance: Maintenance absorbents are ideal for managing everyday spills in industrial, commercial, and indoor settings.

- Chemical Spill Management: When handling hazardous substances, Chemical absorbents offer the necessary protection and efficiency for spill containment.

Choosing a spill absorbent

Whether you're managing an oil spill, dealing with chemical spills, or tackling maintenance tasks, choosing the right absorbent is essential for effective fluid recovery. FyterTech Nonwovens™ offers a wide range of meltblown absorbent pads and absorbent rolls designed for various spill scenarios. Our products provide fast, reliable, and efficient solutions to help you keep your environment safe and clean.

For more information or to get advice on which absorbent product suits your needs, contact us today.

Spill Absorbent Granules

In need of high performance absorbent granules? We offer Absonet recycled granules, Oil-Dri Granules and Spill Aid Granules.

Related Spill Control Blogs: