Spill Control

Spill Control Solutions | FyterTech

Industrial spills - from oils and chemicals to lubricants and hazardous fluids pose serious environmental, legal, and safety risks. A robust spill control strategy protects your site, workforce, and reputation. At FyterTech, our spill control approach blends technical precision with regulatory clarity, ensuring you're ready before a spill occurs.

1. Conduct a Spill Risk Assessment

Effective spill control begins with a detailed risk assessment tailored to your site:

- Identify hazardous liquids: fuels, solvents, chemicals, coolants, hydraulic fluids.

- Estimate spill volumes based on tank sizes, vehicle loads, and transfer processes.

- Analyse site topography to map likely flow paths toward drains, watercourses, and plant areas

2. Select Appropriate Spill Kits & Kits Placement

Choosing and positioning spill kits correctly is central to rapid response effectiveness:

- Kit types: Oil-only, Chemical, Maintenance, and AdBlue. Each designed for specific liquid classes

- Capacity: Choose kits with the right absorption capacity - sizes include 25 L to 1000 L, and always keep extras on-site

- Strategic placement: Locate kits at refuelling stations, chemical handling areas, drains, loading bays, and bunds - within ~30 m of potential spill zones

3. Primary Containment: Immediate Spill Control

When a spill occurs, the initial focus must be on containment:

- Raise the alarm, isolate the area, and notify relevant personnel and authorities if needed

- Secure the source - shut valves, upright containers, or stamp out leaks .

- Deploy absorbents: use socks or booms to contain, pads or granules to absorb, then transfer saturated materials into disposal bags

- Use drain bungs or inflatable stoppers for spills threatening watercourses

4. Secondary Containment Systems

Beyond immediate absorption, preventing environmental leakage is vital:

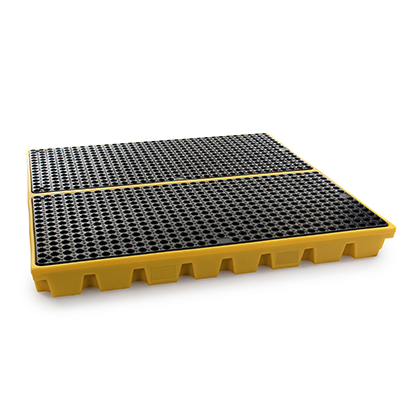

- Bunded drip trays &spill pallets for drums and containers

- Regular bund integrity checks: visual inspections annually & hydrostatic tests as required

5. Cleanup & Waste Management

Cleaning is only part of the solution - proper disposal is essential:

- Collect used absorbents in labelled hazardous waste bags for removal

- Decontaminate surfaces and equipment

- Maintain detailed incident logs for regulatory reporting and liability documentation

6. Training, Drills & Cultural Embedment

The best spill plans collapse without trained staff:

- Induction training: Kits, PPE, procedures for all new personnel

- Regular drills: Conduct quarterly simulated scenarios, record speed and accuracy, refine procedures

- Promote safety culture: Encourage hazard reporting, feedback, and recognize safe practices .

7. Regulatory Framework: UK Compliance Essentials

Stay aligned with UK spill control regulations:

- COSHH and HSWA require risk assessment, equipment, and training for hazardous substance handling

- Oil Storage Regulations 2001 mandate bunding and containment for ≥200 L stored oil

- Environmental Permitting Regulations & PPG guidance expect PIRPs, bund checks, spill kits, and drain protection.

8. Consequences of Inadequate Spill Response

Failing to act effectively can cost you:

- Safety incidents: Slips, falls, exposure, injuries.

- Environmental damage: Contamination of soil, groundwater, and wildlife.

- Regulatory penalties: Unlimited fines, possible imprisonment, project shutdowns

- Reputational harm: Loss of business and public trust.

9. Choosing the Right Spill Control Partner

FyterTech stands out through:

- Site-specific audits to assess real spill risks.

- Tailored containment solutions, from kits to bunds and berms.

- End-to-end training programmes including drills and competency checks.

- Full compliance support, documentation, and PIRP alignment.

- Ongoing service: kit inspections, restocking, bund testing, and refresher training.

Spill Control FAQs – Quick Guide for Businesses & Workplaces

What should I do if a spill occurs?

If a spill occurs in your workplace:

- Identify the spill – Check the type of liquid (oil, chemical, water, etc.) and any hazards.

- Alert and protect – Inform staff and restrict access

- Contain the spill – Use absorbent socks, booms, or barriers to stop it spreading, especially towards drains.

- Clean up – Apply spill absorbents such as pads, pillows, or granules.

- Dispose safely – Follow local regulations for hazardous waste disposal.

- Report and review – Record the incident and update your spill prevention procedures.

Tip: Keep spill control kits in high-risk areas for a faster, safer response.

What is spill control equipment?

Spill control equipment refers to tools and materials designed to contain, control, and clean up liquid spills in workplaces, warehouses, and industrial sites. Common spill control equipment includes:

- Absorbents – pads, rolls, granules, pillows, and absorbent socks.

- Containment devices – drain covers, spill berms, pallets, and bunds.

- PPE for spill response – gloves, goggles, aprons, respirators.

- Waste containers – hazardous waste bins and disposal bags.

- Spill response signage – to warn and protect other workers.

Having the right spill control equipment ensures quick action and compliance with UK spill control regulations.

How do I use a spill control kit?

To use a spill control kit effectively:

- Access the nearest kit – Kits should be stored close to potential spill areas.

- Wear PPE (if necessary)– Protect yourself first.

- Stop the source – If safe, prevent more liquid from leaking.

- Contain the spill – Place absorbent socks or booms around the spill area.

- Absorb the liquid – Lay down pads, pillows, or granules directly on the spill.

- Dispose correctly – Use the hazardous waste bags provided in the kit.

- Restock immediately – Replace any used items to maintain readiness.

Pro Tip: Train staff on spill kit usage to reduce clean-up times and environmental impact.

Why do you need a spill control kit?

A spill control kit is essential because it:

- Prevents environmental contamination – Stops harmful substances entering drains, soil, or waterways.

- Protects employee safety – Reduces risks from slips, skin contact, or inhalation.

- Ensures legal compliance – Meets environmental and workplace health & safety requirements in the UK.

- Minimises downtime – Speeds up recovery after a spill incident.

- Demonstrates preparedness – Shows auditors, insurers, and customers that safety is a priority.

Bottom line: Without a spill control kit, you risk environmental damage, fines, and workplace accidents.

Related Pages

Follow Us On LinkedIn